Industry 5.0 and the Factory of the Future: A Comprehensive Framework for Human-Centric, Sustainable, and Resilient Manufacturing

Abstract

Industry 5.0 represents a paradigm shift in global manufacturing, transcending the technology- and efficiency-driven focus of Industry 4.0 to prioritize human-centricity, sustainability, and resilience. This article synthesizes technological architectures, enabling technologies, and policy frameworks to articulate a comprehensive vision for the factory of the future. It details the integration of 5G-enabled IoT, augmented reality (AR), computer vision, collaborative robots (cobots), blockchain, modular equipment, wearable technologies, and autonomous logistics, alongside governance and strategic guidelines. The article provides a roadmap for national and international adoption, with specific recommendations for emerging economies such as Bangladesh to achieve operational efficiency, global competitiveness, and sustainable industrial growth.

Introduction

The industrial sector is undergoing a transformative evolution. While Industry 4.0 emphasized digitalization, automation, and operational efficiency, Industry 5.0 introduces a values-driven framework that centers on human welfare, ecological sustainability, and system resilience. This new paradigm envisions industrial ecosystems not merely as profit engines but as instruments of societal well-being, capable of creating inclusive, regenerative, and adaptive production networks.

Pressing global challenges—climate change, biodiversity loss, pandemics, and socio-economic inequities—necessitate a reorientation of industrial priorities. Industry 5.0 addresses these challenges by embedding human empowerment, environmental stewardship, and adaptive capacity into industrial strategy and operations.

Core Pillars of Industry 5.0

Industry 5.0 is structured around three interdependent pillars:

Human-Centricity

Human-centric design emphasizes aligning industrial systems with human skills, safety, and well-being rather than forcing workers to conform to technology. This includes:

- Enhancing worker engagement, safety, and ergonomic conditions.

- Ensuring AI, automation, and digital tools empower rather than replace labor.

- Promoting lifelong learning and reskilling for digitally augmented roles.

Sustainability

Sustainability in Industry 5.0 moves beyond compliance, embedding ecological integrity and circular economy principles into industrial processes:

- Minimizing waste and enabling resource reuse and regeneration.

- Integrating energy-efficient and low-carbon processes.

- Embedding environmental accountability throughout value chains.

Resilience

Resilient manufacturing systems adapt to disruptions, mitigate risks, and ensure continuity:

- Decentralized production and localized supply chains.

- Flexible, modular, and reconfigurable production ecosystems.

- Predictive risk management leveraging AI, big data, and digital twins.

Technological Framework for the Factory of the Future

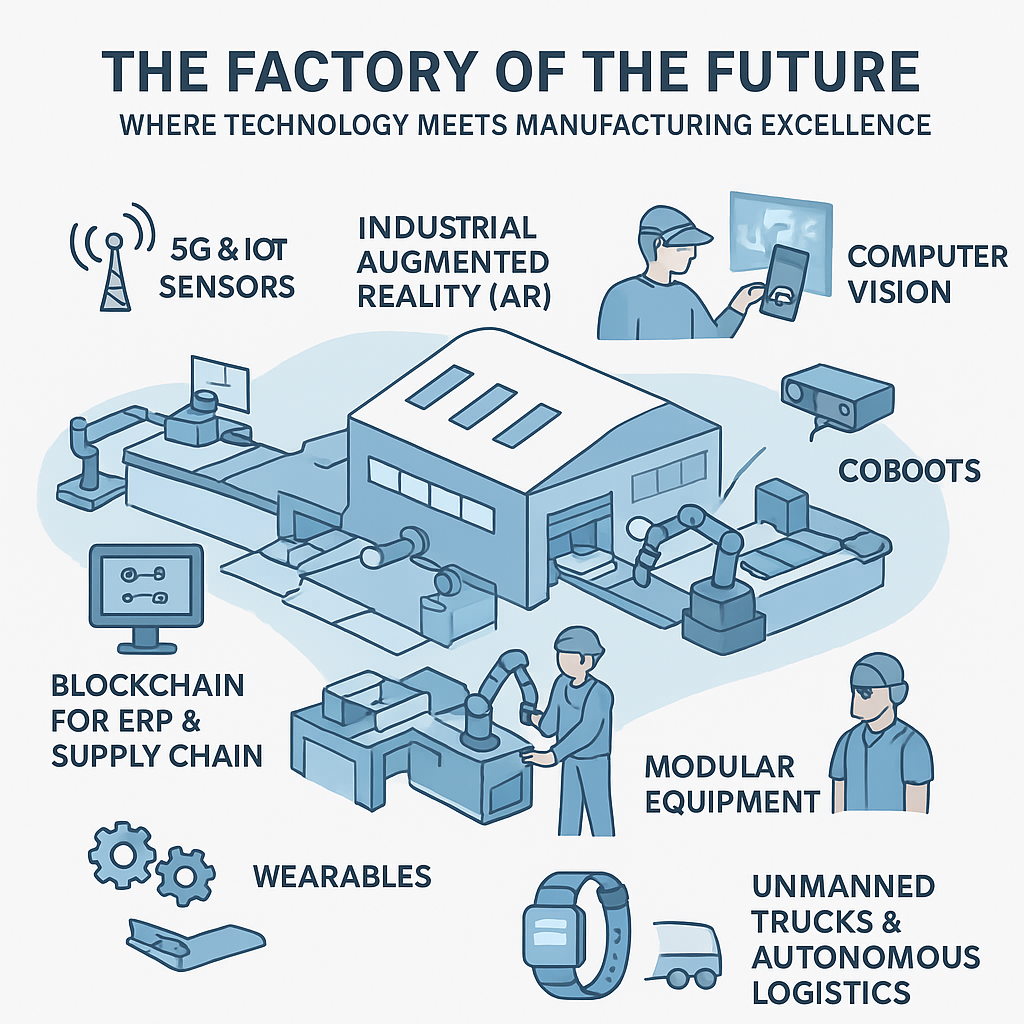

The transition to Industry 5.0 relies on the convergence of digital, physical, and human-centered technologies. Key components include:

5G and IoT Sensors

- Function: Real-time monitoring, predictive maintenance, and energy management.

- Features: High-speed connectivity, edge computing, and industrial-grade sensors.

- Integration: Feeds data into MES, ERP, and AI platforms for prescriptive analytics.

Augmented Reality (AR)

- Function: Provides visual guidance for assembly, maintenance, and training.

- Features: AR headsets with live overlays, workflow instructions, and remote expert support.

- Integration: Coupled with IoT and wearable devices for context-aware guidance.

Computer Vision

- Function: Automated quality inspection, defect detection, and robotic guidance.

- Features: AI-powered image analysis (YOLO, Mask R-CNN), 3D vision, high-resolution cameras.

- Integration: Alerts production systems, guides cobots, and ensures product quality.

Collaborative Robots (Cobots)

- Function: Assist humans in precision tasks while ensuring safety.

- Features: AI-enabled task adaptation, modular attachments, proximity sensors.

- Integration: Operates alongside humans, guided by AR and computer vision feedback.

Blockchain

- Function: Ensures supply chain transparency, traceability, and compliance.

- Features: Immutable ledgers, smart contracts, integration with IoT data.

- Integration: Supports regulatory compliance and export traceability mandates.

Modular Equipment

- Function: Enables rapid reconfiguration of production lines.

- Features: Interchangeable modules, plug-and-play connectivity, digital twin simulation.

- Integration: Works in synergy with cobots, IoT, and AI to adapt production in real-time.

Wearables

- Function: Monitors worker health, safety, and productivity.

- Features: Smart helmets, gloves, vests with heart rate, motion, and environmental sensors.

- Integration: Communicates with AR, AI, and IoT platforms to ensure proactive safety measures.

Autonomous Logistics

- Function: Automates intra-factory and last-mile logistics.

- Features: AGVs, drones, AI-optimized routes, real-time obstacle detection.

- Integration: Links with warehouse management systems, blockchain, and 5G networks for efficient operations.

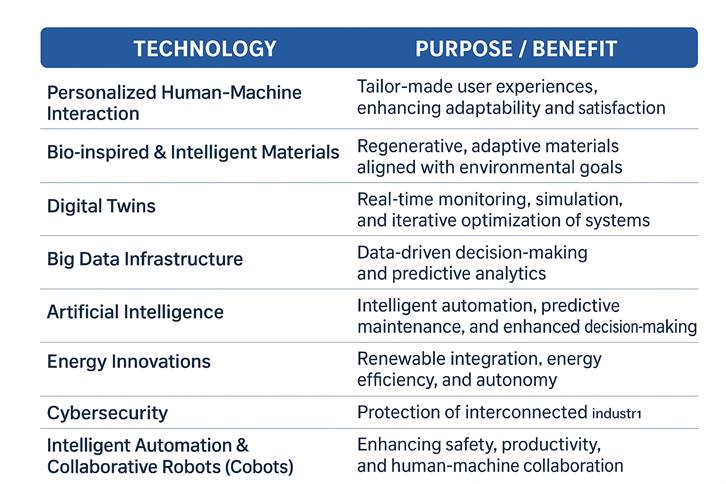

Enabling Technologies

The European Commission identifies several core enabling technologies critical for operationalizing Industry 5.0:

These technologies collectively enable the integration of human-centricity, sustainability, and resilience into industrial operations.

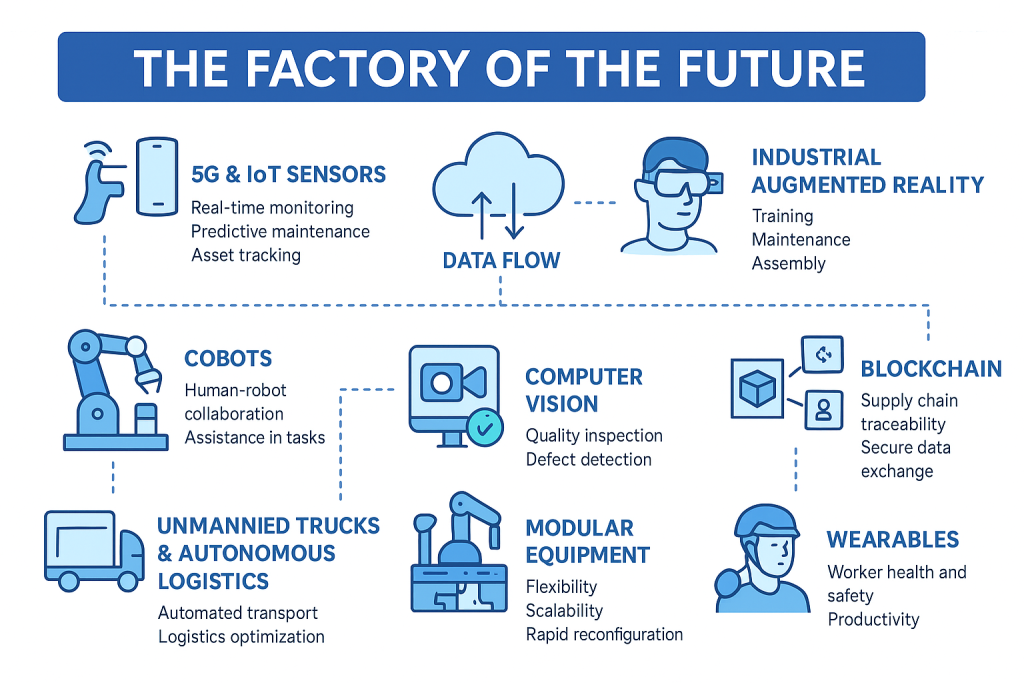

Data Flow and Cyber-Physical Integration

The factory of the future relies on a continuous cyber-physical loop:

- Data Capture: Sensors, wearables, and IoT devices gather environmental, machine, and human data.

- Edge & Cloud Computing: Processes data in real-time for analytics and storage.

- AI & Computer Vision: Optimize processes, detect defects, and guide robotic operations.

- AR & Cobots: Deliver context-aware instructions to humans and robots.

- Modular Equipment: Adjust production lines based on AI insights and market demands.

- Blockchain: Secures data and ensures traceability.

- Autonomous Logistics: Moves goods efficiently, coordinated in real-time.

Each technology layer contributes to a cyber-physical system where data flows seamlessly from sensors and machines to decision-making platforms, and back into adaptive equipment and empowered workers.

This integration creates self-optimizing, adaptive, and resilient manufacturing ecosystems.

Adoption Trajectory

Adoption of Industry 5.0 technologies follows a phased trajectory:

Short Term (1–3 years): IoT predictive maintenance, AR training, cobots in hybrid work cells, computer vision QA.

Medium Term (3–7 years): Blockchain pilots, modular equipment deployment, private 5G networks, data hub integration.

Long Term (7–10 years): Autonomous logistics, widespread wearables, self-regulating supply chains with human oversight.

Policy and Strategic Guidelines for Bangladesh and Emerging Economies

To operationalize Industry 5.0, governments and industry must collaborate across infrastructure, skills, regulation, and innovation domains:

- Digital Infrastructure: Invest in nationwide 5G, cloud, and IoT networks.

- Technology Adoption Incentives: Provide tax breaks, grants, and PPP models for AR, AI, cobots, and blockchain.

- Skills & Training: Reskill the workforce in AI, robotics, AR/VR, and data analytics.

- Sustainability Compliance: Implement blockchain-based traceability in sectors like textiles, RMG, and agri-food exports.

- Pilot Smart Factories: Launch government-industry collaborations for Industry 5.0 demonstration plants.

- Safety & Standards: Define national standards for industrial wearables, cobots, and autonomous vehicles.

- Policy Coherence: Align national strategies with global ESG standards and EU/US market regulations.

Benefits of Integrated Industry 5.0 Architecture

- Operational Efficiency: Predictive maintenance, higher throughput, reduced downtime.

- Human-Centric Production: Enhanced safety, ergonomics, and training.

- Resilient Supply Chains: Real-time visibility, risk mitigation, and adaptive logistics.

- Sustainability: Energy efficiency, circular economy adoption, and reduced carbon footprint.

- Global Competitiveness: Compliance with international standards and readiness for advanced markets.

Conclusion

The Factory of the Future is not a distant vision but an evolving operating model. By sequencing the adoption of 5G IoT, AR, cobots, blockchain, modular equipment, wearables, and autonomous logistics, emerging economies can strengthen global competitiveness while advancing sustainability and resilience. Industry 5.0 is a technological, ecological, and ethical transformation that empowers humans while regenerating resources.

Engr. Johnny Shahinur Alam

Technologist and ICT & Digital Transformation Specialist

.